The Future of Automated Manufacturing: Robotics and Machine Learning in Industry

The manufacturing landscape is undergoing a transformative shift with the integration of robotics and machine learning, heralding a new era of efficiency and sustainability. As industries strive to meet growing demands while minimizing environmental impact, these advanced technologies are proving to be invaluable tools.

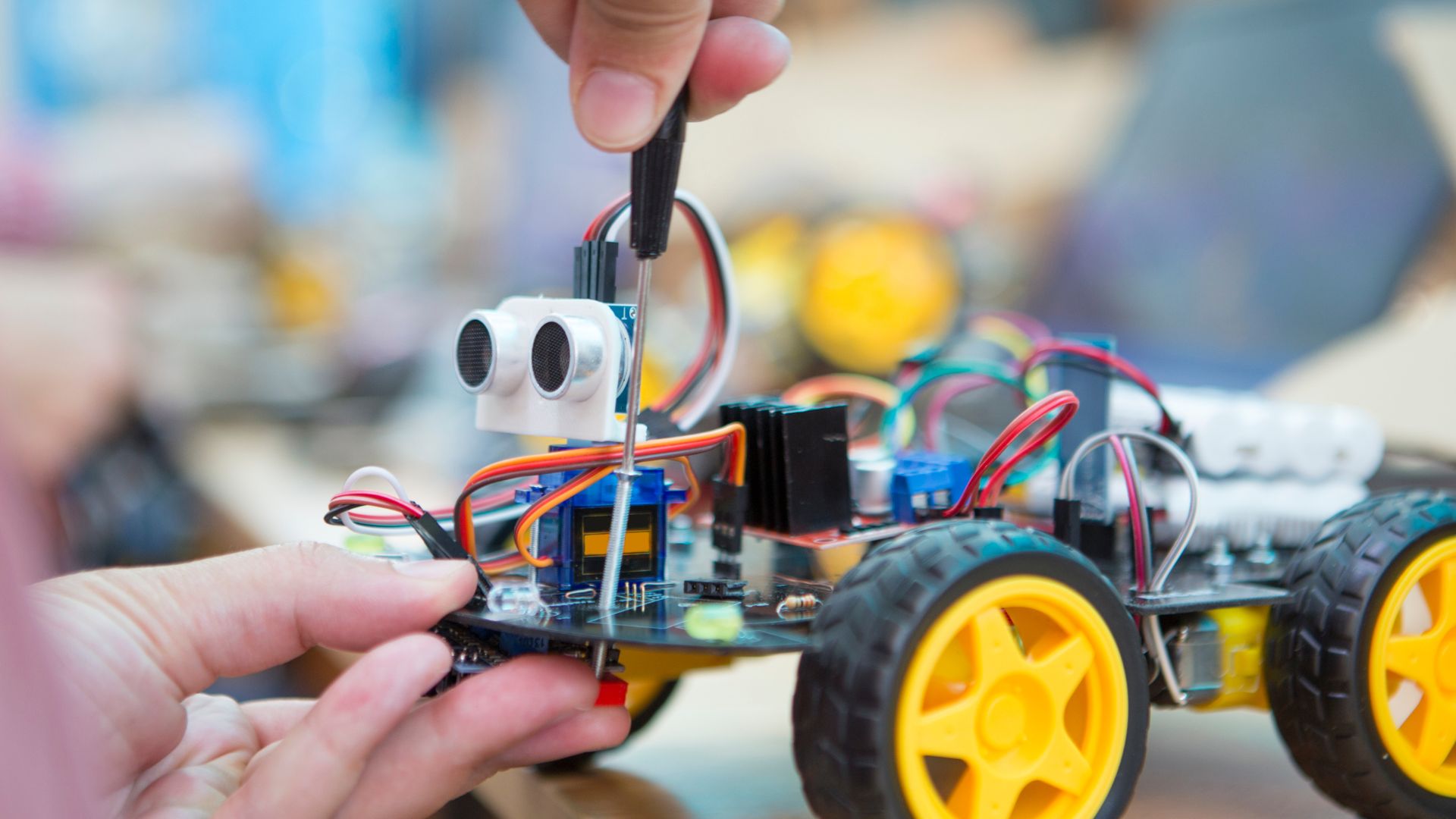

Robotics has been a cornerstone of automation in manufacturing, with robots performing tasks that are repetitive, precise, and often hazardous for humans. Recent advancements in robotic technology have significantly enhanced their capabilities, enabling robots to handle more complex and delicate operations. Collaborative robots, or cobots, are designed to work alongside human workers, combining the strengths of both human intelligence and robotic efficiency. These cobots can adapt to changing tasks, learn from human interactions, and ensure a safer working environment by reducing the risk of accidents.

Machine learning, a subset of artificial intelligence, complements robotics by providing the systems with the ability to learn from data and improve over time. In manufacturing, machine learning algorithms analyze vast amounts of data generated by sensors, machines, and processes to optimize production lines, predict equipment maintenance needs, and reduce energy consumption. This predictive maintenance capability helps prevent unexpected breakdowns, thereby minimizing downtime and prolonging the life of machinery.

The synergy between robotics and machine learning is particularly powerful in enhancing sustainability. For instance, automated systems can optimize the use of materials, reducing waste and ensuring that resources are used efficiently. Machine learning algorithms can also predict energy usage patterns and optimize the operation of machines, contributing to lower energy consumption and reduced carbon footprints.

Furthermore, these technologies facilitate the adoption of flexible manufacturing systems, which can quickly adapt to changes in production demands and customize products to meet specific needs. This flexibility reduces the need for large inventories and helps manufacturers respond to market trends more swiftly, minimizing waste and improving resource efficiency.

As robotics and machine learning continue to evolve, their role in manufacturing will expand, driving innovation and paving the way for a more efficient, sustainable, and adaptable industrial future. The integration of these technologies not only boosts productivity but also aligns with global sustainability goals, showcasing the potential of automated manufacturing to create a positive impact on both industry and the environment.